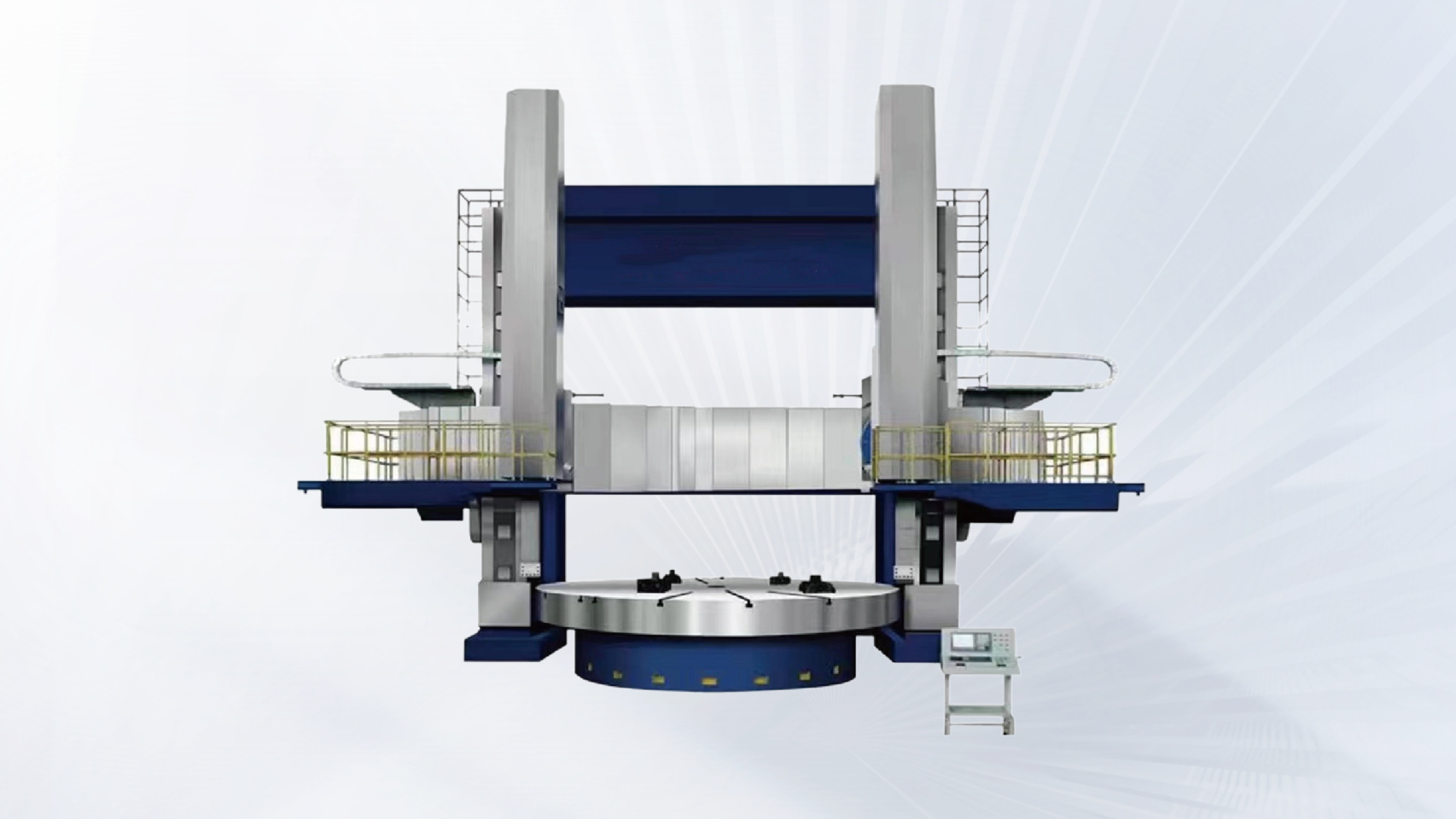

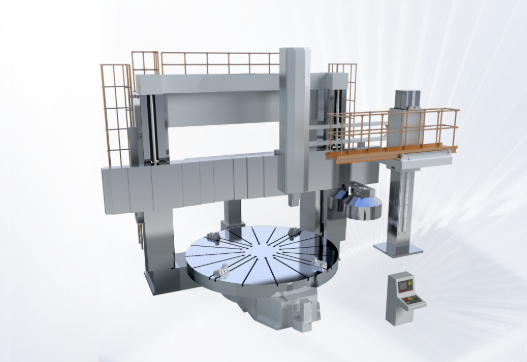

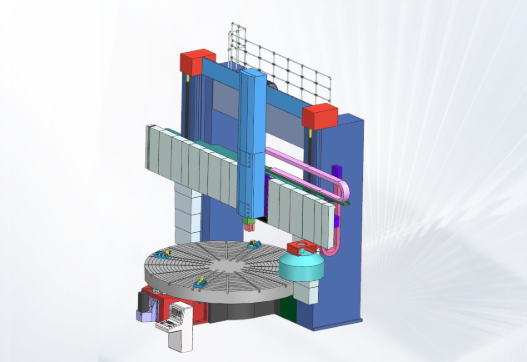

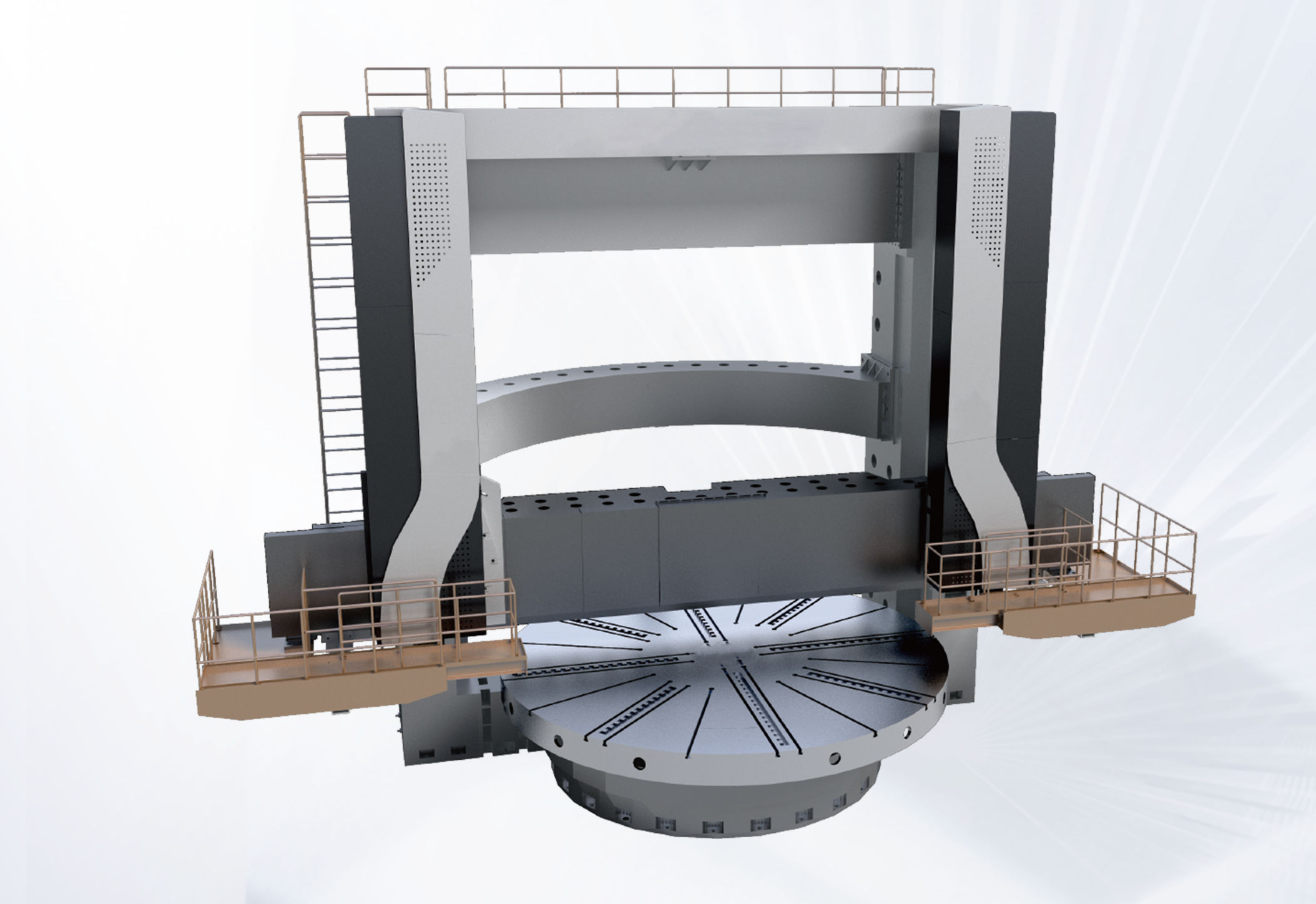

This series of machine tools is an upgraded version of ordinary vertical lathes, retaining the original gantry frame and worktable main transmission, instead of the traditional trapezoidal screw and self-made gear feed box.

lt is upgraded to a servo feed motor with planetary reducer and ball screw transmission. Make the structure simpler, the operation more convenient, and the low failure rate.

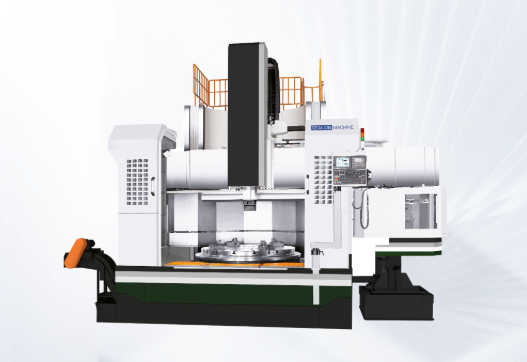

This type of machine tool is widely used in industries such as machinery, mining and metallurgy, automotive, and power.

lt has the characteristics of stable accuracy, easy operation, safety and reliability and long service life.

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES