- Home

-

Machines

Machines

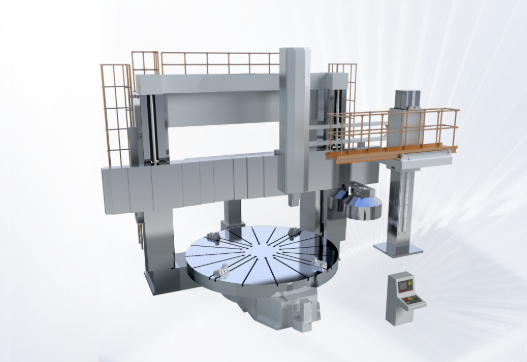

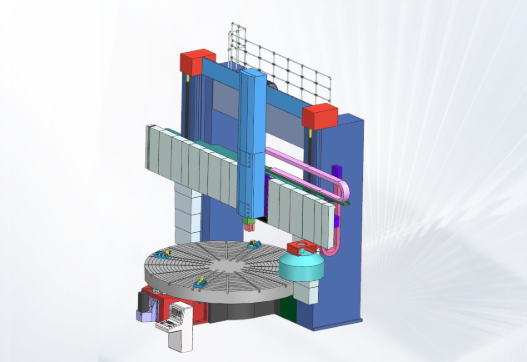

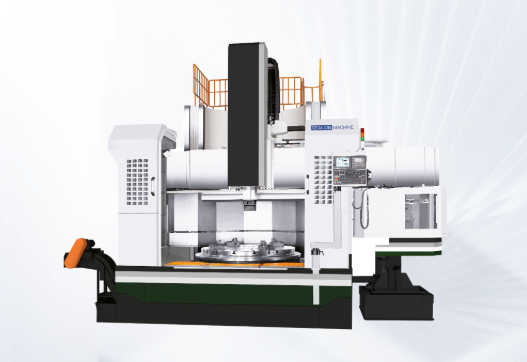

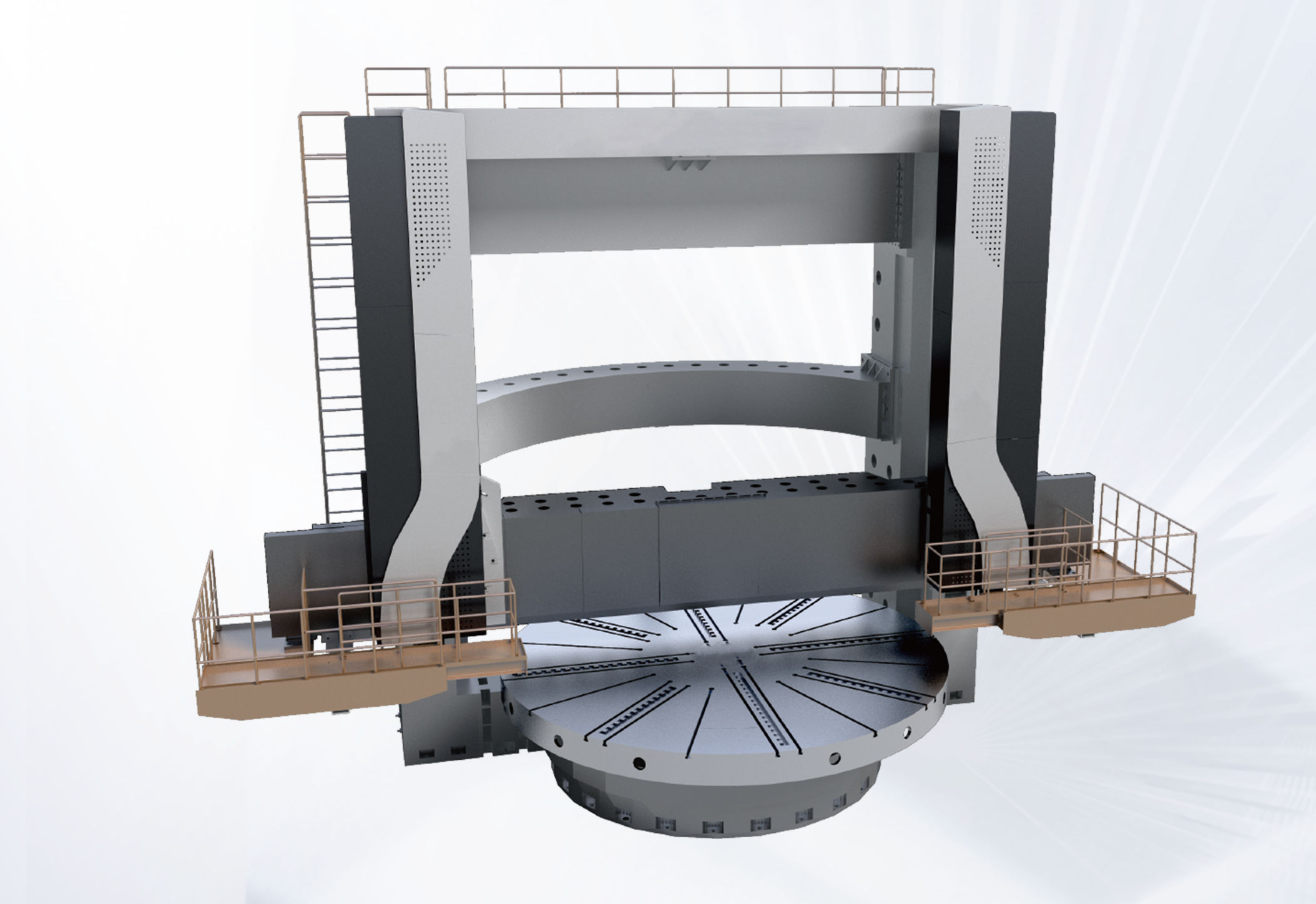

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES

CH51T DOUBLE LIFTING WITH ATC SERIES CK51T DOUBLE LIFTING SERIES DVT51 VERTICAL LATHE CK51D SERIES CNC VERTICAL LATHECK5225E DOUBLE COLUMN VERTICAL LATHE CK5250D CNC DOUBLE COLUMN VERTICAL LATHE CK5225D VERTICAL LATHE DVT5225D DOUBLE COLUMN VERTICAL LATHECH SERIES MACHINE WITH ATC HT SERIES VERTICAL MACHINE CENTER CHS51T HIGH SPEED DOUBLE LIFTING WITH ATC CKS51T HIGH SPEED DOUBLE LIFTING SERIES - Videos

- Application

- Service

- About Us

- Down load

- Contact Us