Vertical Lathe Machine Operation and Maintenance Precautions

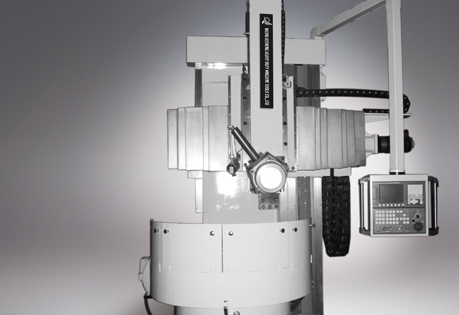

What is a Vertical Lathe Machine?

The spindle of a vertical lathe machine is vertical and there is a circular worktable for mounting the workpiece. Since the worktable is in a horizontal position, it is easy to align and clamp the workpiece, and the gravity of the workpiece and worktable is supported by the bed guide or thrust bearing, and the spindle does not bend. Therefore, the vertical lathe is suitable for machining large disc-shaped and short sleeve-shaped parts.

The vertical tool holder on the vertical lathe machine can move along the crossbeam guide and the tool holder seat guide for horizontal or vertical feeding. The tool holder seat can be tilted at a certain angle for oblique feeding. The side tool holder can move up and down along the column guide, or move left and right along the tool holder slide to achieve longitudinal or transverse feeding.

The vertical lathe machine is a large mechanical equipment, and it is used for machining large and heavy workpieces with large radial dimensions and relatively small axial dimensions and complex shapes. Various disc-shaped, wheel-shaped and sleeve-shaped workpieces, such as cylindrical surfaces, end faces, conical surfaces, cylindrical holes, conical holes, etc., can also be machined with additional devices for turning threads, turning ball surfaces, contouring, milling and grinding.

Precautions for Using the Vertical Lathe Machine

The rough surface of the workpiece should not be placed directly on the worktable surface, and should be supported by a pad or spiral end support. It is strictly prohibited to use the worktable surface for other operations, such as hammering to correct the workpiece or welding the workpiece, etc.

When aligning the workpiece, only low-speed rotation of the worktable can be used to align it, and high-speed alignment is not allowed on the vertical lathe machine.

When starting or stopping the worktable, the worktable start/stop handle can only be operated by hand, and it is strictly prohibited to use the foot pedal.

When the worktable is rotating, it is not allowed to move the crossbeam up and down or move the tool holder quickly.

When moving the crossbeam of the vertical lathe machine, the clamping device should be loosened first, and it should be clamped immediately after moving. After each downward movement of the crossbeam, it should be raised slightly to eliminate the gap between the screw and the nut.

It is not allowed to perform gravity cutting when the vertical tool holder and side tool holder slide are extended for a long distance; when using the vertical tool holder for machining, especially for gravity cutting, the beam should be lowered as close to the working position as possible.

When performing intermittent cutting, the vertical lathe machine should reduce the feed rate and worktable rotation speed appropriately.

The control lever must be pushed to the specified position during speed change. If the gears are not meshed properly, adjustments should be made after work is performed, and forced operation is not allowed.

Precautions for Maintaining the Vertical Lathe Machine

Extend the life of components and the wear cycle of parts, prevent various failures, improve the average fault-free working time and service life of the vertical lathe machine.

The environment for using the vertical lathe machine

The vertical lathe machine is best placed in a constant temperature environment and away from equipment with large vibrations (such as punches) and equipment with electromagnetic interference.

Power requirements

The vertical lathe machine should have operating procedures for regular maintenance and maintenance, and attention should be paid to record and protect the scene when failures occur.

The vertical lathe machine should not be sealed for a long time.

Pay attention to training and equipping operators and maintenance personnel for the vertical lathe machine.

Strictly abide by the operating procedures and daily maintenance system.

Prevent dust and floating dust from entering the electrical control device. Dust and metal powder can easily cause the insulation resistance to decrease between electrical components, causing failures or even damage to components.

Regularly clean the ventilation system of the vertical lathe machine's electrical control cabinet.

-

Maintenance and Operation Procedures for Horizontal Boring Machine

The operator of horizontal boring machine must be familiar with the general performance and structure of the machine, transmission system, and over-performance use is strictly prohibited.Before operat... -

Characteristics and Advantages of Single-Column Vertical Lathe

What is a Single Column Vertical Lathe?A single column vertical lathe is a type of lathe, specifically a versatile ordinary lathe from the vertical lathe series. It is suitable for machining various s... -

What is the Difference Between CNC Machine Tools and Conventional Machine Tools?

Machine tool is a machine that manufactures machines, and it is also a machine that can manufacture machine tools itself. Turning, milling, planing, grinding, boring, drilling, electrical discharge ma...