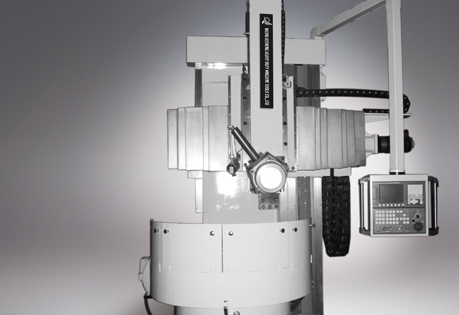

A CNC Lathe that is Not Free of Programming is Not a Good Lathe

In 2020, in a modern industry with rapid technological development, production and processing will also consume high labor costs and high production costs. The whole process is high consumption and low efficiency. This is completely derailed from the development of Industry 4.0 and is obviously far from meeting the requirements of modern industry.

Production and processing must be low-consumption and high-efficiency, which can be started from two aspects, including machine tools and systems. As long as the structure of the CNC lathe is reasonable, the spare parts are used well, the accuracy, rigidity and stability of the CNC lathe are guaranteed, and the quality control is done well, basically the CNC lathe is fine. The system is different. Most CNC lathes use conventional CNC systems. If the system is different, the difference is big. It is obvious in terms of convenience and stability of use.

If you want a CNC lathe with less labor, less cost, low consumption and high efficiency, a system without programming is undoubtedly the best choice. Programming-free means no need of programming. Copy the CAD drawing directly into the system, set the total depth and drilling depth, set the automatic tool setting, set the feed speed and spindle parameters, and you can start with one key. Operators do not need to understand G codes at all. It is foolish operation. Those who know how to play with mobile phones can operate it, and it can be started in 3 minutes with zero basis.

One person can control multiple CNC lathes without programming. Programming-free CNC lathe do not require professional programmers to write programs or operator operators. You can easily get started with zero foundation. It directly reduces the number of workers in the workshop by 80%, reduces production costs by 70%, and increases productivity by 200%!

-

Reduce Machine Tool Standby Time To Improve Equipment Energy Efficiency

Because of the increasing cost of energy, the energy consumption of machine tools has attracted more and more attention. By so far, the peripheral equipment and auxiliary facilities of the equipment ... -

Differences Between Vertical Lathes and Horizontal Lathes

In the field of machine tools, vertical lathes and horizontal lathes are suitable for different machining needs due to their structure and mode of operation. This article will compare the characterist... -

What Products Are Suitable for Gantry-type Machining Centers?

In modern manufacturing, gantry-type machining centers, with their superior processing capabilities and precision, have become the preferred equipment for handling large and complex workpieces. Compar...